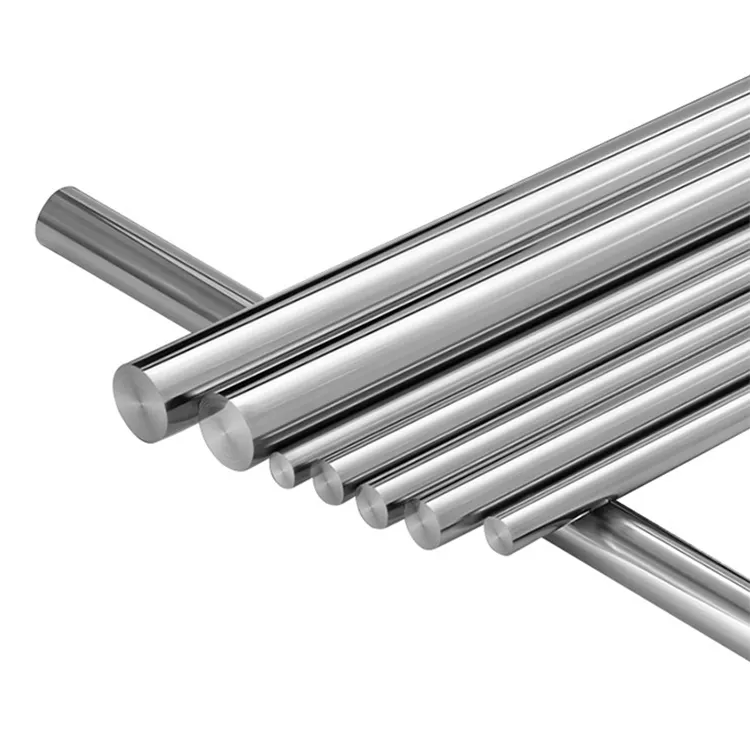

2023 China ASTM 12L 13 DIN 1.3255 JIS Skh3 T4 High Speed Tool Steel Round Bar FREE CUTTING STEEL BAR

We often stay with the principle “Quality Very first, Prestige Supreme”. We have been fully committed to supplying our consumers with competitively priced high-quality goods, prompt delivery and skilled provider for 2023 China ASTM 12L 13 DIN 1.3255 JIS Skh3 T4 High Speed Tool Steel Round Bar FREE CUTTING STEEL BAR, Our corporation is dedicated to furnishing customers with high and steady top quality products at aggressive price tag, making just about every customer glad with our services and products.

We often stay with the principle “Quality Very first, Prestige Supreme”. We have been fully committed to supplying our consumers with competitively priced high-quality goods, prompt delivery and skilled provider for 12L13 FREE CUTTING STEEL BAR, To keep the leading position in our industry, we never stop challenging the limitation in all aspects to create the ideal solutions. In his way, We can enrich our life style and promote a better living environment for the global community.

Product Detail

12L13 12L14 12L15 are free cutting structural steel. Free cutting steel is a type of steel that is easy to cut (such as turning, milling, pulling, planing, drilling, etc.), also known as automatic machine tool processing steel, abbreviated as automatic steel. is easy cutting structural steel, easy cutting steel is easy to be (turning, milling, drawing, planing, drilling, etc.) cutting processing steel, also known as automatic machine tool processing steel, referred to as automatic steel. It is produced to adapt to machining automation and flow line production.

Standard: ASTM A29/A29M-04

12L13 12L14 12L15 belong to lead sulfur composite free cutting structural steel. In the lead free cutting steel, the lead is distributed in the steel with tiny simple metal particles and does not solidify in the steel. During the cutting process, strong friction occurs between the tool and the work piece, making the lead particles in the steel melt out, thus playing a lubricating role to improve the cutting performance of the steel, making the steel chips finely broken, reducing tool wear, and ultimately extending the tool life. Compared with the steel without lead, the cutting performance of the steel with lead can be improved by 20~50%, while the mechanical properties and heat treatment properties remain basically unchanged, and the cold and hot working properties and weld ability are not affected. Lead free cutting steel has been widely used in the manufacturing of precision instrument parts, automotive parts, and important parts of various machinery. However, the contact fatigue of lead free cutting steel is low, so it is not suitable for gears, bearings and other components that bear high fatigue stress loads.

Parameters

|

Size |

Round Bar | Dia 6-1200mm |

|

|

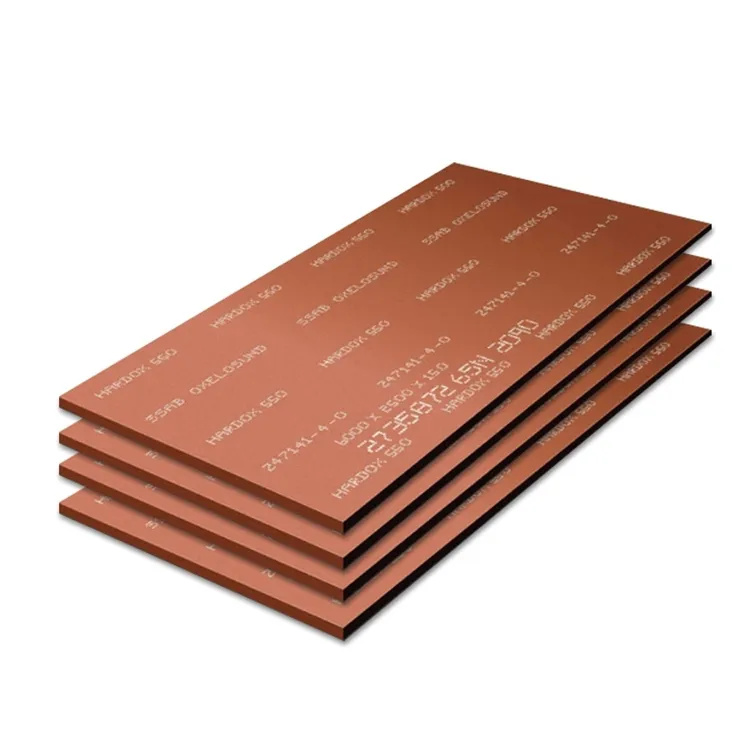

Plate/Flat/Block | Thickness: 6mm-500mm |

|

|

Width: 20mm-1000mm | |

| Heat treatment | Normalized ; Annealed ; Quenched ; Tempered | |

| Surface condition | Black; Peeled; Polished; Machined; Grinded; Turned; Milled | |

| Delivery condition | Forged; Hot rolled; Cold drawn | |

| Test | Tensile strength, Yield strength, elongation, area of reduction, impact value, hardness, grain size, ultrasonic test, US inspection, magnetic particle testing, etc. | |

| Application | 12L13 12L14 12L15 free-cutting steel is mainly used for making instruments, watches, parts, automobiles, machine tools and other machines with small stress and strict requirements on size and finish. Standard parts with strict requirements for dimensional accuracy and smoothness and relatively low requirements for mechanical properties, such as gear, shaft, bolt, valve, bushing, pin, pipe joint, spring seat and machine tool lead screw, plastic molding die, surgical and dental procedures tools, etc. | |

| Chemical Composition (%) | ||||||

|

Grade |

C |

Si |

Mn |

P |

S |

Pb |

|

12L13 |

≤0.13 |

≤0.02 |

0.70-1.00 |

0.07-0.12 |

0.24-0.33 |

0.15-0.35 |

|

12L14 |

≤0.15 |

≤0.02 |

0.85-1.15 |

0.04-0.09 |

0.26-0.35 |

0.15-0.35 |

|

12L15 |

≤0.09 |

≤0.02 |

0.75-1.05 |

0.04-0.09 |

0.26-0.35 |

0.15-0.35 |

| Equal different standards | ||||

|

AISI/ASTM |

GB |

EN10087 |

JIS |

DIN |

|

12L13 |

Y08Pb |

11SMnPb30 |

UM23L |

|

|

12L14 |

Y12Pb |

11SMnPb37 |

SUM24L |

1.0718 |

|

12L15 |

Y15Pb |

- |

SUM24L |

|

Package&Shipping

Quality Assurance

1.Strict according to Requirements

2.Sample: Sample is available.

3. Tests: Salt spray test/Tensile test / Eddy current / Chemical composition test according to customers’ request

4.Certificate: IATF16949, ISO9001, SGS etc.

5. EN 10204 3.1 Certification

1: What is 1213 free cutting steel?

1213 free cutting steel is a high-strength, wear-resistant low-carbon alloy steel widely used in the manufacturing of mechanical components and automotive bodies. It has good strength, toughness, and corrosion resistance, and is easy to process and form. In addition, 1223 free cutting steel also has excellent fatigue resistance and can effectively extend its service life. 1213 free cutting steel is mainly used for making mechanical equipment components and automotive body parts. This includes door frames, steering wheel bearing blocks, and light components. They are usually made of high-quality low-carbon alloy steel or medium carbon manganese steel, which is formed and heat treated on a cold/hot extrusion machine. Material characteristics of 1213 free cutting steel:

1213 free cutting steel is a high-strength steel that can withstand large external loads;

1213 free cutting steel has high hardness and strong impact resistance;

3. 1213 free cutting steel has strong wear resistance and is not easily corroded;

1213 free cutting steel has excellent durability and can be used for a long time;

5. 1213 free cutting steel is easy to cut and is not affected in any way.

2: What are the uses of 1213 free cutting steel?

1213 free cutting steel is mainly used in automotive manufacturing, aerospace, and other high-end applications. They have good corrosion resistance and can be processed at lower temperatures, making them an ideal choice for metal materials. These advantages make 1213 free cutting steel the preferred product in many industries. 1213 free cutting steel is also widely used in daily life, such as making furniture and daily necessities. In addition, 1213 free cutting steel is widely used in aviation manufacturing, aerospace industry, and military equipment manufacturing. Therefore, 1213 free cutting steel is a very important steel variety.