20CrMnTi 20MnCr5 Steel tube for gear ring SAE5130H SAE4140 gearbox tube

The commonly used steels for manufacturing gears include quenched and tempered steel, quenched steel, carburized quenched steel, and nitrided steel. The strength of cast steel is slightly lower than that of forged steel, and it is commonly used for larger gears; Grey cast iron has poor mechanical properties and can be used in light load open gear transmissions;

Ductile iron can partially replace steel in manufacturing gears; Plastic gears are mostly used in places with light loads and low noise requirements, and their paired gears are generally made of steel gears with good thermal conductivity.

In the future, gears are developing towards heavy-duty, high-speed, high-precision, and high-efficiency directions, striving for small size, light weight, long service life, and economic reliability.

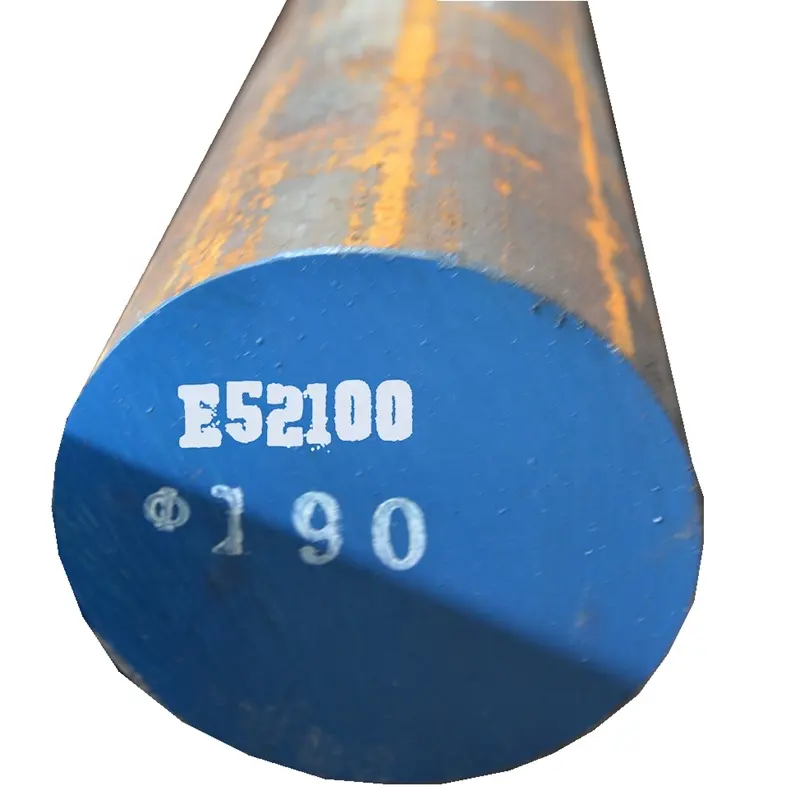

The material grades of quenched and tempered steel used for manufacturing gears include: 45 # steel, 35SiMn, 42SiMn, 50SiMn, 40Cr, 35CrMo, 42CrMo, 37SiMn2MoV, 40CrMnMo, 40CrNi, 38SiMnMo, 42CrMo4V.

The material grades of carburized steel used for manufacturing gears are 20Cr, 20CrMnTi, 20CrMnMo, 38CrMoAl, 17CrNiMo6, 12Cr2Ni4, 20Cr2Ni4, and 20CrNi3.

The material grades of cast steel and alloy cast steel used for manufacturing gears include ZG 310-570, ZG 340-640, ZG 40Mn2, ZG 35SiMn, ZG 42SiMn, ZG 50SiMn, ZG 40Cr, ZG 35CrMo, and ZG 35CrMnSi.

The material grades of gray cast iron and ductile iron used for manufacturing gears include HT250, HT300, HT350, QT500-7, QT600-3, QT700-2, QT800-2, and QT1200-1.

Specification

Application:

Gearbox of all kinds(AT/MT/DCT/CVT etc.),Engine,synchronizer main reducing gear, coupling gear, balance gear, sun gear, planetary gear,etc. Of passenger carsand commercial vehicles.

Common Steel Grade:

16-20MnCr5 、5130H、4140、34CrS4

Delivery Condition:

HR、Norm、ANN、QT

Advantages:

●Simplify the process: Reduce energy consumption and improve production

●Good economic benefits: Customized service ,non-standard rolling and high material utilization

●Low risk of material processing: Direct processing can avoid the risk of forging cracking and coarse grain size.

Application Cases