34CrS4 S45C 40Cr SAE8620 Gear Ring steel tube Gear Box steel tube

As a transmission component, gears have been widely used in machinery. It can transmit power through gears and has a certain positioning function. As an important machining method, gear machining always relies on the use of steel. So what are the commonly used types of steel?

1. Quenched steel: As one of the commonly used steels for gear processing, it not only has high hardness but also does not produce plastic changes during the processing, making it widely used.

2. Carburized and quenched steel: Many manufacturers use carburized and quenched steel as a gear processing steel. This steel can enhance the hardness of carburized gears, and it needs to have better wear resistance during use. These issues are commonly used steel in gear processing. Only by selecting our own suitable steel based on specific usage situations can we truly achieve the best processing effect.

3. Quenched and tempered steel: Gear processing usually uses quenched and tempered steel, which can achieve good comprehensive mechanical properties when processing parts. It not only maintains high strength, but also has a certain degree of plasticity and toughness.

Specification

Common Steel Grade:

34CrS4 S45C 40Cr SAE8620 、16-20MnCr5 、5130H、4140、34CrS4

Delivery Condition:

HR、Norm、ANN、QT

Advantages:

●Simplify the process: Reduce energy consumption and improve production

●Good economic benefits: Customized service ,non-standard rolling and high material utilization

●Low risk of material processing: Direct processing can avoid the risk of forging cracking and coarse grain size.

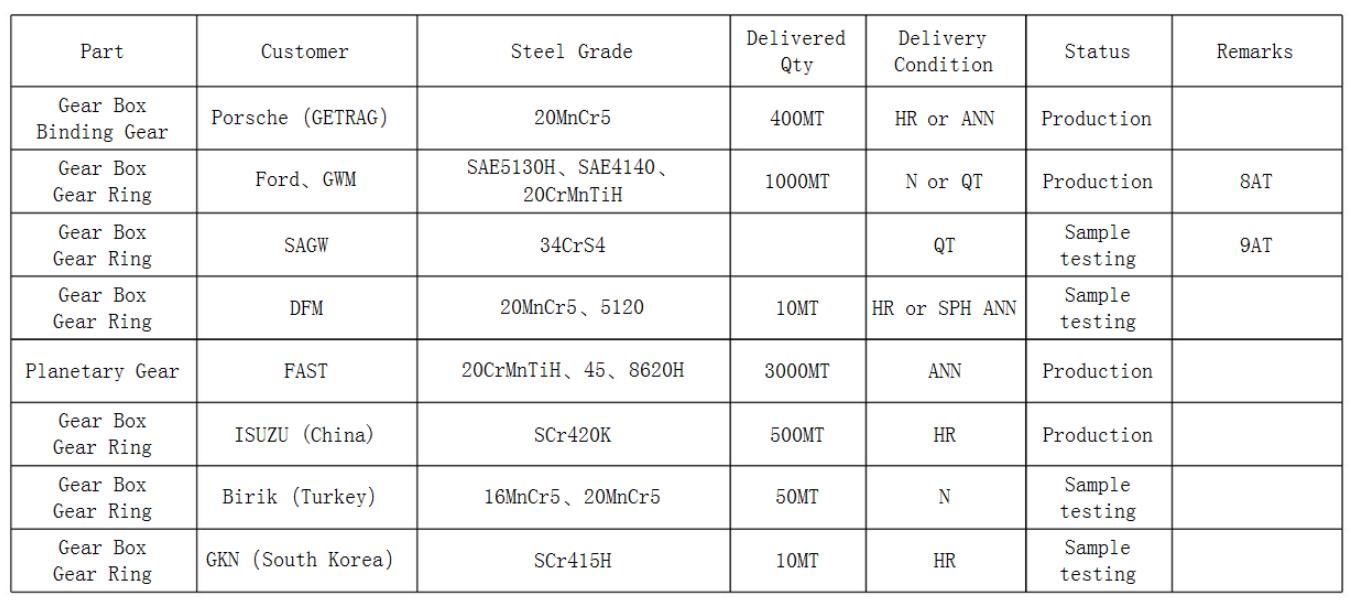

Application Cases