AISI 4340 4130 4140 HRC Hot Cold Rolled Steel Coil CRC Cold Rolled Steel Coil

No matter new consumer or outdated shopper, We believe in lengthy expression and trusted relationship for AISI 4340 4130 4140 HRC Hot Cold Rolled Steel Coil CRC Cold Rolled Steel Coil, All price ranges depend upon the quantity of your respective buy; the much more you purchase, the far more economical the rate is. We also offer fantastic OEM assistance to many famous brands.

No matter new consumer or outdated shopper, We believe in lengthy expression and trusted relationship for AISI 4130 coil, For more than ten years experience in this filed, our company has gained high reputation from home and abroad. So we welcome friends from all over the world to come and contact us, not only for business, but also for friendship.

Product Detail

4130 is a structural steel made in the United States. Executive standard: ASTM A29

4130 steel (also known as AISI 4130 and SAE 4130) is a chromium molybdenum low alloy steel with much higher strength and toughness than typical steel grades. In addition, the carbon content of this alloy is reduced while limiting the thickness strength, providing better weld ability than its 4140 steel counterpart. These characteristics make AISI 4130 a popular choice in the aerospace industry for manufacturing commercial and military aircraft components that require high strength and low weight. Examples include gears, piston pins, etc. Other uses of 4130 steel include automotive parts, cutting tools, and drilling and mining machinery.

Specification

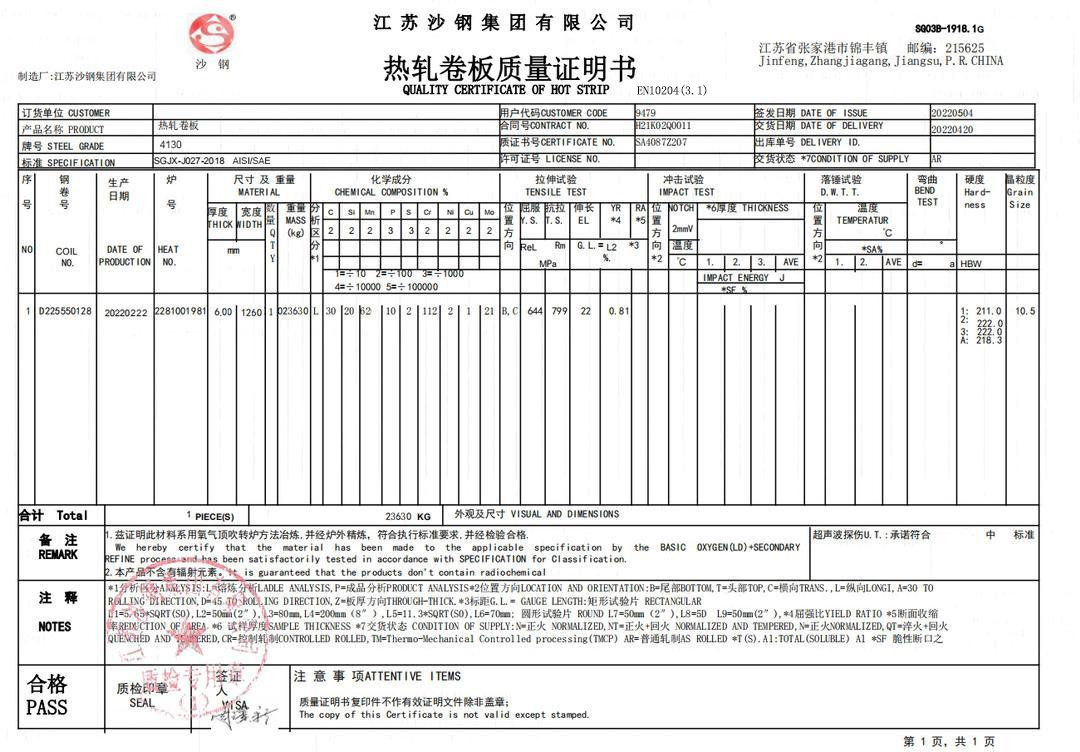

| Chemical composition of 4130 alloy steel coil(%) | |||||||

|

C |

Si |

Mn |

P |

S |

Cr |

Mo |

|

|

0.28-0.33 |

0.15-0.3 |

0.4-0.6 |

0.035 |

<0.04 |

0.8-1.1 |

0.15-0.25 |

|

| Mechanical properties of 4130 alloy steel | |||||

| Tensile strength | Yield strength | Elongation | Hardness, | Modulus | Reduction |

| 560Mpa | 460Mpa | 21.50% | HB 217 | 190-210 Gpa | 59.6 |

Fabrication and Heat Treatment

Machinability

4130 steel can be easily machined using conventional methods. However, machining becomes difficult when the hardness of the steel is increased.

Forming

Forming of 4130 steel can be performed in the annealed condition.

Welding

Welding of 4130 steel can be performed by all commercial methods.

Heat Treatment

4130 steel is heated at 871°C (1600°F) and then quenched in oil. This steel is usually heat-treated at temperatures ranging from 899 to 927°C (1650 to 1700°F).

Forging

Forging of 4130 steel can be performed at 954 to 1204°C (1750 to 2200°F).

Hot Working

Hot working of 4130 steel can be done at 816 to 1093°C (1500 to 2000°F).

Cold Working

4130 steel can be cold worked using conventional methods.

Annealing

4130 steel can be annealed at 843°C (1550°F) followed by air cooling at 482°C (900°F).

Tempering

Tempering of 4130 steel can be performed at 399 to 566°C (750 to 1050°F), depending on the desired strength level.

Hardening

Hardening of 4130 steel can be done with cold working or heat treatment.

4130 Alloy Cold Rolled Steel Sheets offer good weld ability without compromising steel abrasion and impact resistance. It is commonly used in structural applications, including gears, fasteners, and some aircraft exterior.

Annealed Steel is “softer” than normalized steel and offers higher work ability while normalized steel offers a higher strength tolerance.

4130 Steel has good mach-inability, good weld ability and can be heat treated. Our material is annealed and meets AMS 6350.

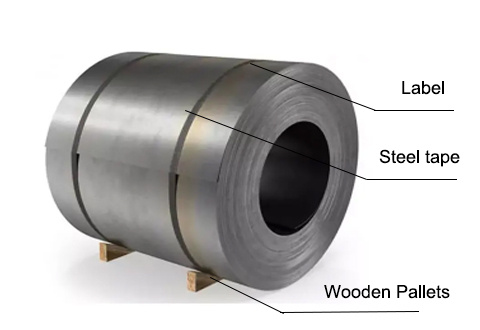

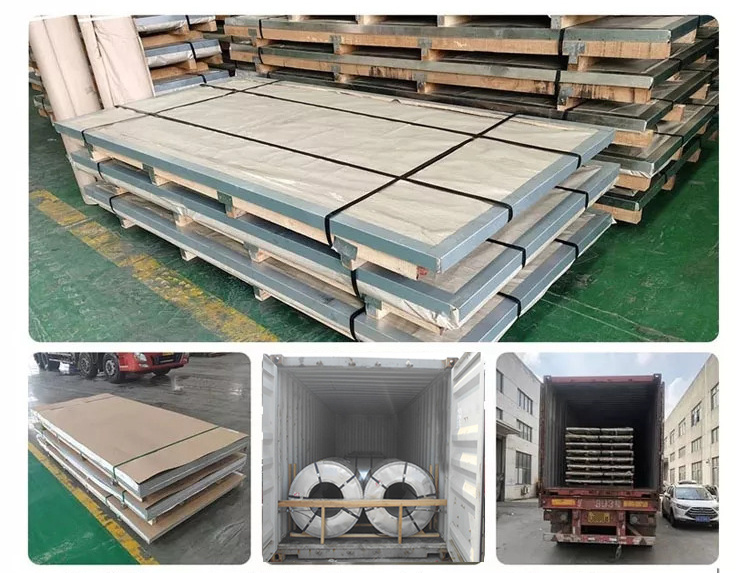

Package&Shipping

By bundles, each bundle weight under 3 tons, for small outer

Diameter round bar, each bundle with 4 – 8 steel strips.

20 feet container contains dimension, length under 6000mm

40 feet container contains dimension, length under 12000mm

By bulk vessel, Freight charge is low by bulk cargo, and large

Heavy sizes can not be loaded into containers can shipping by bulk cargo

No matter new consumer or outdated shopper, We believe in lengthy expression and trusted relationship for China Factory for AISI 4340 4130 4140 HRC Hot Cold Rolled Steel Coil and CRC cold rolled steel coil, All price ranges depend upon the quantity of your respective buy; the much more you purchase, the far more economical the rate is. We also offer fantastic OEM assistance to many famous brands.

4130 structural steel has high strength and toughness, high hardenability, and a critical hardenability diameter of 15-70mm in oil; The thermal strength of steel is also good, with sufficient high-temperature strength below 500 ℃, but its strength significantly decreases at 550 ℃; When the alloy element is at the lower limit, welding is quite good, but when it is close to the upper limit, the weldability is medium, and preheating to above 175 ℃ is required before welding; Steel has good machinability and moderate plasticity during cold deformation; There is the first type of temper brittleness in the range of 300-350 ℃ during heat treatment; There is a tendency to form white spots.

China Factory for China Carbon Steel and Ms Steel, For more than ten years experience in this filed, our company has gained high reputation from home and abroad. So we welcome friends from all over the world to come and contact us, not only for business, but also for friendship.