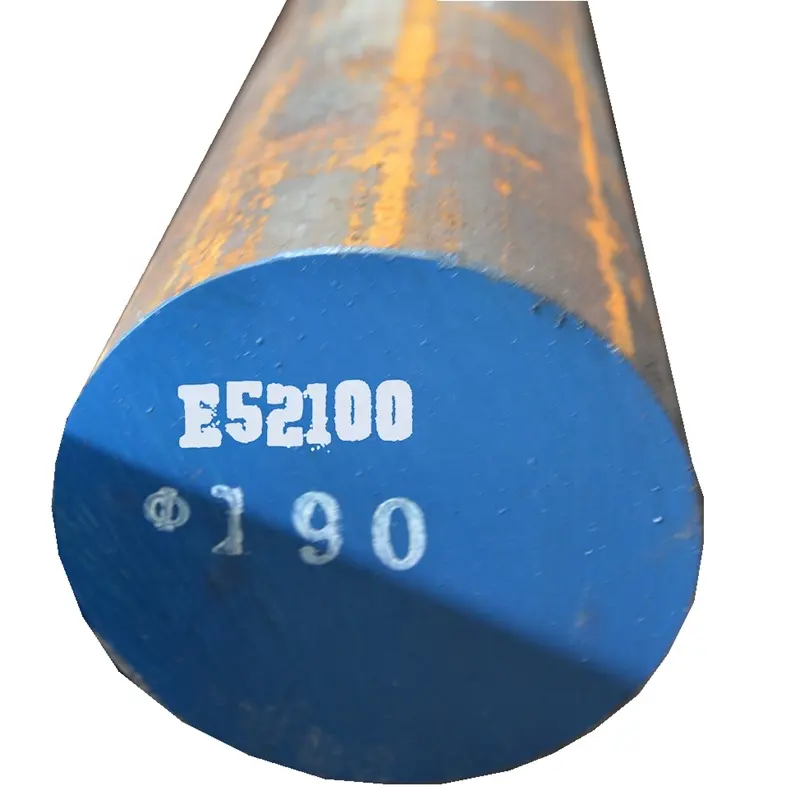

Bearing Steel GCr15 AISI 52100 100Cr6 and SUJ2 Bearing Round Bar

Product Details

Bearing steel is the steel used to manufacture balls, rollers, and bearing rings. Bearing steel has high and uniform hardness, wear resistance and high Elastic Limit. The requirements for the uniformity of chemical composition, the content and distribution of non-metallic inclusions, and the distribution of carbides in bearing steel are very strict. The bearing material is made of high carbon steel. High carbon steel is often called Tool steel, with carbon content ranging from 0.60% to 1.70%, which can be quenched and tempered. Hammers, crowbars, etc. are made of steel with a carbon content of 0.75%.

The heat treatment process for bearing steel consists of two main steps: pre heat treatment and final heat treatment. GCr15 steel is the most widely used type of bearing steel, a high carbon chromium bearing steel with low alloy content and good performance. GCr15 bearing steel has high and uniform hardness, good wear resistance, and high contact fatigue performance after heat treatment.

Most bearings use SUSJ2, a type of JIS steel, which is domestic chromium steel (GCr15).

The chemical composition of SUJ2 has been standardized as a bearing material in various countries around the world. For example, it belongs to the same type of steel as AISI52100 (USA), 100Cr6 ( Germany), BS535A99 (UK), etc..

Parameters

| Size | Round Bar | OD10mm-1600mm |

| Plate/Flat/Block bars | Thickness6mm-500mm | |

| Width20mm-1000mm | ||

| Heat treatment | Normalized ; Annealed ; Quenched ; Tempered | |

| Surface condition | Black; Peeled; Polished; Machined; Grinded; Turned; Milled | |

| Delivery condition | Forged; Hot rolled; Cold drawn | |

| Test | Tensile strength, Yield strength, elongation, area of reduction, impact value, hardness, grain size, ultrasonic test, US inspection, magnetic particle testing, etc. | |

| Payment terms | T/T;L/C;/Money gram/ Paypal | |

| Trade terms | FOB; CIF; C&F; etc.. | |

| Delivery time | 30-45 days | |

Equal Bearing Steel Grade

|

Country |

German |

Japan |

British |

CHN |

USA |

|

Standard |

DIN 17230 |

JIS G4805 |

BS 970 |

|

ASTM A295 |

|

Grades |

100Cr6/1.3505 |

SUJ2 |

535A99/EN31 |

Gcr15 |

52100 |

Chemical Composition(%)

|

Grade |

C |

Si |

Mn |

P |

S |

Cr |

Mo |

Ni |

|

EN31/535A99 |

0.95-1.10 |

0.10-0.35 |

0.25-0.40 |

0.04 |

0.05 |

1.20-1.60 |

/ |

/ |

|

52100/1.3505 |

0.93-1.05 |

0.15-0.35 |

0.25-0.45 |

0.025 |

0.015 |

1.35-1.60 |

0.10 |

0.30 |

|

SUJ2 |

0.95-1.10 |

0.15-0.35 |

0.50 |

0.025 |

0.025 |

1.30-1.60 |

0.08 |

0.25 |

|

GCr15 |

0.95-1.05 |

0.15-0.35 |

0.25-0.45 |

0.025 |

0.025 |

1.40-1.65 |

0.10 |

0.30 |

Applications

Bearing steel is a type of steel used to manufacture rolling bearings, such as balls, rollers, and sleeves. It can also be used to make precision measuring tools, cold stamping dies, machine tool screws, precision components such as dies, measuring tools, taps, and diesel engine oil pumps. Bearing steel is the steel used to manufacture balls, rollers, and bearing rings.