Cold Drawn /Cold Rolled Seamless Steel Pipe tubing

New Gapower Metal is professional manufacturer of hydraulic steel pipe.With an annual production of 10,000 tons of high precision seamless steel tube and 20,000 tons polished steel bar and hot rolled bar.

Sample characteristic Introduction

Profile

1.Seamless steel tube

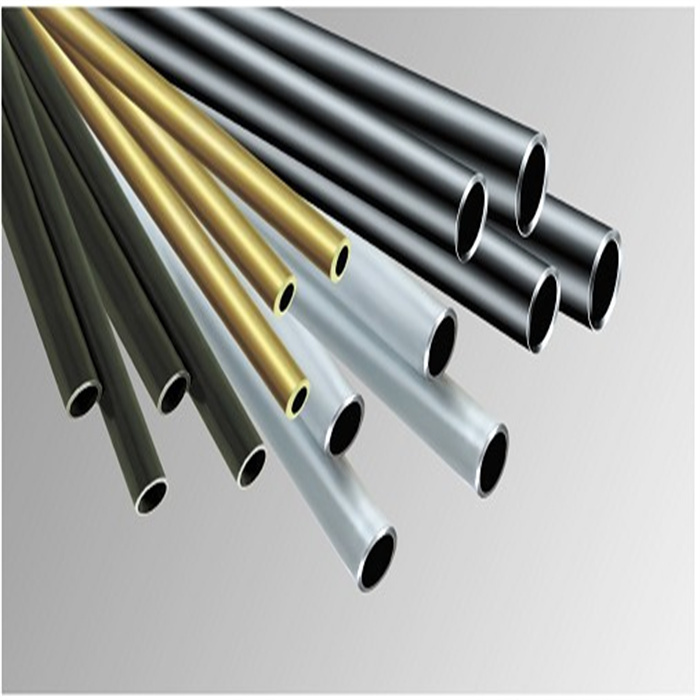

2.Widely used in the hydraulic cylinder of the heavy machinery, Cranes, excavator also forklifts. Material is various, mainly E355/ST52 ST35/E235 ST37.4 ST45/E255 4140 4130 S45C STKM11A STKM12B etc. We can also offer as customized seamless steel tube.

3.2.Cold drawn steel tube/cold rolled steel tube

4.Grade: 20# 45# 16Mn 25Mn 27SiMn E355 ST52 STKM11A STKM13A

5.Standard: GB/T8713 GB/T3639 DIN2391 EN10305 ASTMA519

6.Range: 30-300mm

7.Length: 11m(max)

8.The cold process can change the thickness of tube to meet client's request and offer better mechanical property.3. SRB&Honed steel tube, honed tube

2.Widely used in the hydraulic cylinder of the heavy machinery, Cranes, excavator also forklifts. Material is various, mainly E355/ST52 ST35/E235 ST37.4 ST45/E255 4140 4130 S45C STKM11A STKM12B etc. We can also offer as customized seamless steel tube.

3.2.Cold drawn steel tube/cold rolled steel tube

4.Grade: 20# 45# 16Mn 25Mn 27SiMn E355 ST52 STKM11A STKM13A

5.Standard: GB/T8713 GB/T3639 DIN2391 EN10305 ASTMA519

6.Range: 30-300mm

7.Length: 11m(max)

8.The cold process can change the thickness of tube to meet client's request and offer better mechanical property.3. SRB&Honed steel tube, honed tube

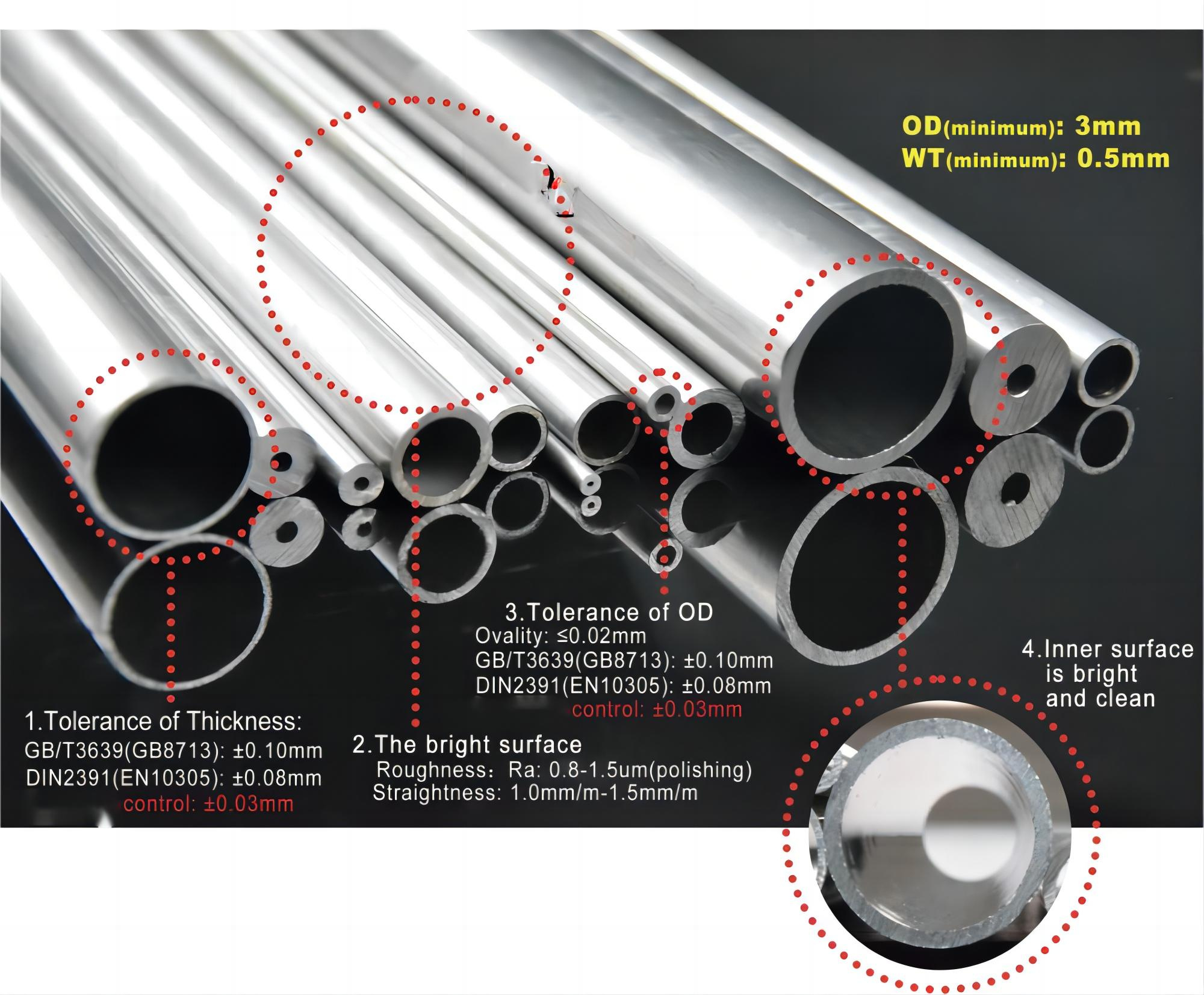

ID Tolerance: H8 H9

ID Roughness: RA0.4micron(max)

Length: 6m(max)

Inner roughness: Ra0.2-0.8um

Straightness: 1:1000 or customized

This process can improve the roughness of the inner tube to 0.2-0.8um and make inside tube more smooth which can be used for cylinder directly.

- Hydraulic cylinder tube, hydraulic tube, cylinder tube

Mechanical properties

| Condition | Materail Grade | T.S (MPa) | Y.S (MPa) | Elongation(%) |

| BKS | ST35 (10#) | ≥420 | ≥315 | ≥14 |

| BKS | ST45(20#) | ≥520 | ≥375 | ≥12 |

| BKS | ST52(16Mn) | ≥580 | ≥420 | ≥10 |

| GBK | ST35 (10#) | ≥315 | ≥35 | |

| GBK | ST45(20#) | ≥390 | ≥32 | |

| GBK | ST52(16Mn) | ≥490 | ≥30 | |

| NBK | ST35 (10#) | 340-470 | ≥235 | ≥32 |

| NBK | ST45(20#) | 440-570 | ≥255 | ≥30 |

| NBK | ST52(16Mn) | 490-630 | ≥335 | ≥28 |

Quality assurance

1.Strict according to DIN2391/EN10305 or other standards.

2. Sample: Sample is free for test.

3. Tests: Salt spray test/Tensile test / Eddy current / Chemical composition test according to customers' request

4.Certificate: IATF16949, ISO9001, SGS etc.

5.EN 10204 3.1 Certification

Product package