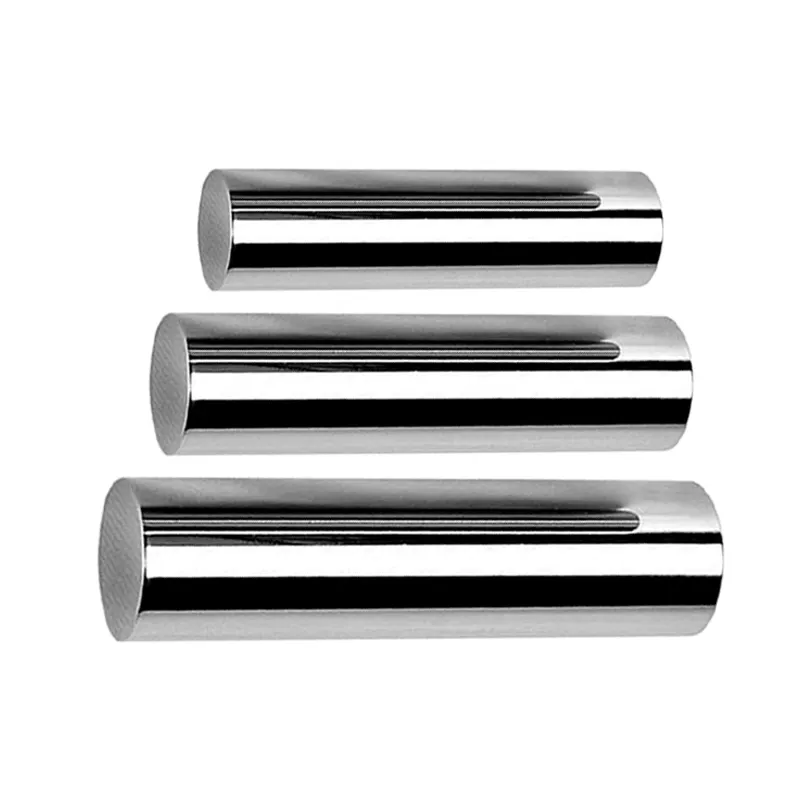

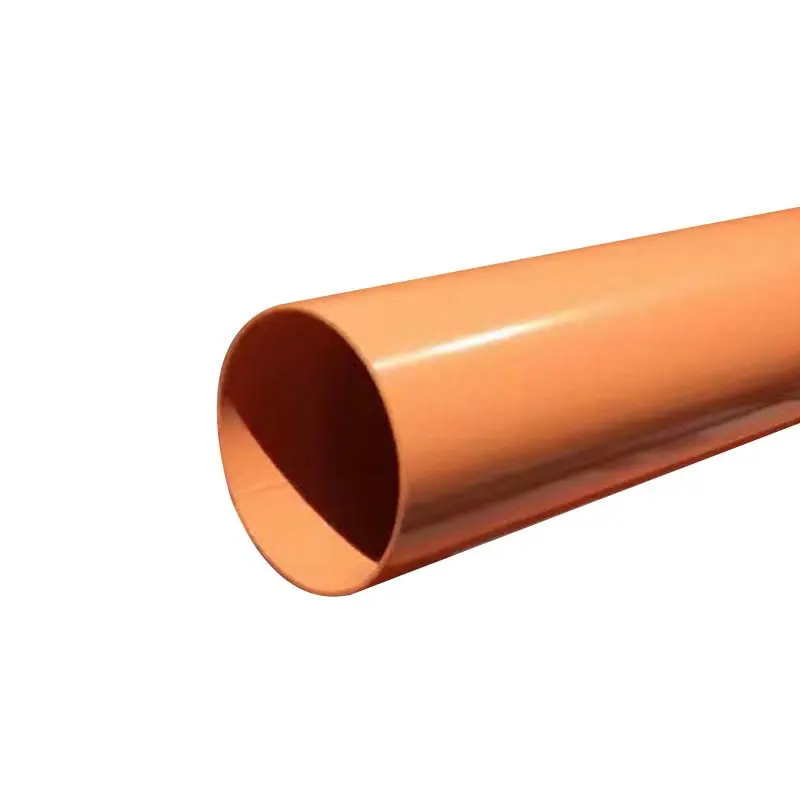

DIN 1.3505 100Cr6 bearing steel tube

Product Details

DIN1.3505 bearing steel is a kind of high quality alloy bearing steel, which belongs to high carbon and low alloy steel containing chromium. 1.3505 Oil quench and temper quench hardness 28-34 HRc. DIN W-NR 1.3505 Steel annealed delivery hardened less than 250 HB.

DIN1.3505 steel is widely used in various applications of rotating machinery bearings. Typical applications such as valve bodies, pumps and fittings, high loads on wheels, bolts, studs,gears, internal combustion engines. Steel balls, rollers and shaft sleeves on transmission shafts of electric locomotives, machine tools, tractors, rolling equipment, roadheaders, railway vehicles and mining machinery.

Parameters

| Size | Round Pipe | OD10mm-130mm

WT2mm-20mm |

| Plate/Flat/Block bars | Thickness6mm-500mm | |

| Width20mm-1000mm | ||

| Heat treatment | Normalized ; Annealed ; Quenched ; Tempered | |

| Surface condition | Black; Peeled; Polished; Machined; Grinded; Turned; Milled | |

| Delivery condition | Forged; Hot rolled; Cold drawn | |

| Test | Tensile strength, Yield strength, elongation, area of reduction, impact value, hardness, grain size, ultrasonic test, US inspection, magnetic particle testing, etc. | |

| Payment terms | T/T;L/C;/Money gram/ Paypal | |

| Trade terms | FOB; CIF; C&F; etc.. | |

| Delivery time | 30-45 days | |

Equal Bearing Steel Grade

|

Country |

German |

Japan |

British |

CHN |

USA |

|

Standard |

DIN 17230 |

JIS G4805 |

BS 970 |

|

ASTM A295 |

|

Grades |

100Cr6/1.3505 |

SUJ2 |

535A99/EN31 |

Gcr15 |

52100 |

Chemical Composition(%)

|

Grade |

C |

Si |

Mn |

P |

S |

Cr |

Mo |

Ni |

|

EN31/535A99 |

0.95-1.10 |

0.10-0.35 |

0.25-0.40 |

0.04 |

0.05 |

1.20-1.60 |

/ |

/ |

|

52100/1.3505 |

0.93-1.05 |

0.15-0.35 |

0.25-0.45 |

0.025 |

0.015 |

1.35-1.60 |

0.10 |

0.30 |

|

SUJ2 |

0.95-1.10 |

0.15-0.35 |

0.50 |

0.025 |

0.025 |

1.30-1.60 |

0.08 |

0.25 |

|

GCr15 |

0.95-1.05 |

0.15-0.35 |

0.25-0.45 |

0.025 |

0.025 |

1.40-1.65 |

0.10 |

0.30 |

Mechanical Properties

| Steel Name (Steel Number) | Tensile Strength (MPa) | Yield Strength (MPa), ≥ | Elongation (%, ≥) | Hardness

(HBW,≤) |

|

1.3505 |

1080-1470 |

835 |

9 |

207(Annealed) |

|

|

830-1130 |

590 |

10 |

241(Annealed) |

Heat Treatment

Annealing : Slowly heat to 872° C (1600° F) and then slowly cool to reduce cold working or machining stresses. Different annealing methods will give different hardness. 1.3505 Bearing steel will obtain hardness MAX 248 HB.

Quenching : Heat slowly to 816° C (1500° F) and quench in oil to obtain a hardness of 62 – 66 HRc. High temperature tempering: 650-700℃, air cooled, hardness 22-30HRC. Low temperature tempering: 150-170℃, hardness: 61-66 HRC.

Applications

DIN1.3505 Alloy Seamless Tube & Pipe For Bearing

1.For making all kinds of bearing ring and rolling element, such as steel ball roller and ferrule of inernal combustion engine, electric motorcycle, automonilrd tractors, machine tools, rolling mill, boring machine, mining machinery, general machinery, high load and high speed roating mechanical transmission bearing.

2.Sometimes also used to make tools, such as pumching die and measuring tools.

3.The automotive and aircraft industry use DIN1.3505 for a number of different applications including.

4. Anti-friction bearings

5.Mill rolls

6.Taps

7.Punches

8. Aircraft parts