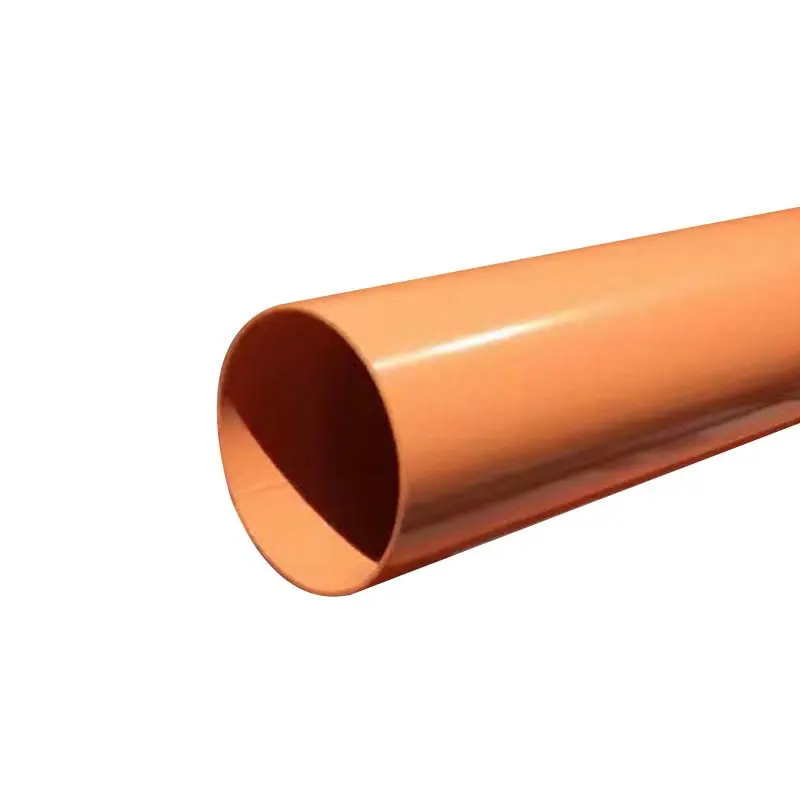

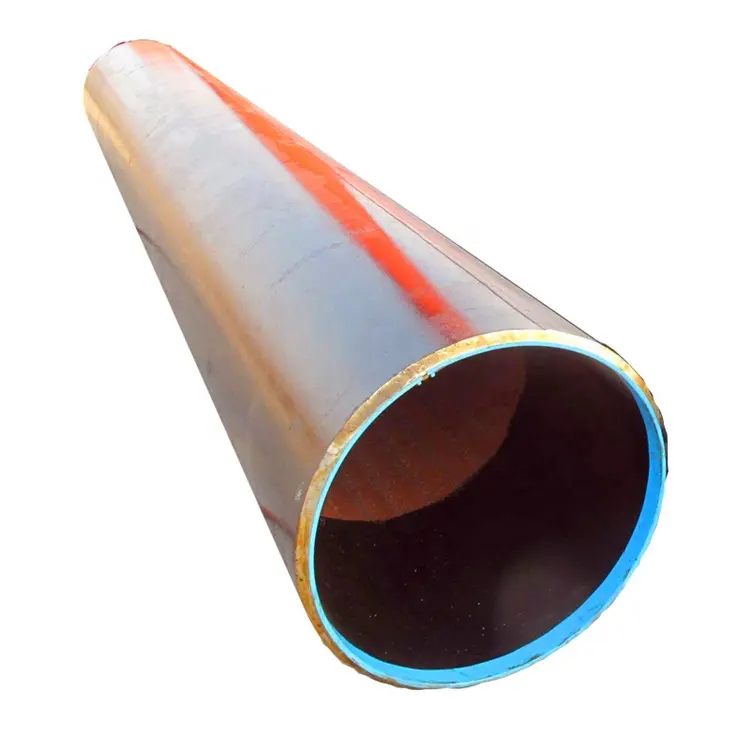

JIS G3429 STH12 STH22 34Crmo4 Steel tube for CNG Cylinder

Product Details

High pressure gas cylinder tube is a kind of seamless steel tube, commonly known as seamless steel tube for gas cylinders, widely used in all kinds of high pressure vessel tanks, as well as industrial gas cylinders, fire cylinders, vehicle CNG cylinders, vehicle c

The main material of gas cylinder tube is: 38Mn6, 30CrMo4, Group , 4130X, Grade C, Grade E, STH11, STH12, STH21, STH22.

The standard JIS G3429 specified seamless steel tubes used for the manufacture of seamless steel gas cylinders. JIS 3429 tubes shall be classified into 5 grades, Grade STH22 tubing is a medium and low carbon chromium-molybdenum type used for pressure vessel made by seamless manufacturing methods. The service environment of high pressure gas cylinders put forward higher requirements for the performance of the steel tube,

material STH22 is more widely used as a cylinder material in high load working environment due to its high strength at high temperature and excellent creep strength.

34CrMo4 is an alloy structural steel with high endurance and creep strength at high temperatures, it is equal with STH22 steel grade. It's mainly used for cylinder manufacturing or structural parts working under high loads such as transmission parts of vehicles and engines; turbine-generator rotor, spindle, heavy load drive shaft, large section parts, locomotive traction gear, supercharger transmission gear, rear shaft, connecting rod and spring clamp with great load, can also be used for the oil drilling pipe joints and fishing tools below 2000m.

Dimensions

Outside diameter: 40-500mm

wall thickness: 4-50mm

Dimensional tolerances

Tolerance on outside diameter :+/- 1%

Tolerance on wall thickness : +30 / -0%

Tolerance on eccentricity : 20 max %

Tolerance on length : +30 / -0 mm

Chemical composition(%)

| Symbol of grade | C | Si | Mn | P | s | Ni | Cr | Mo |

| STH11 | 0.50 max. | 0.10 to 0.35 | 1.80 max. | 0.035 max. | 0.035 max. | / | / | / |

| STH12 | 0.30 to 0.41 | 0.10 to 0.35 | 1.35 to 1.70 | 0.030 max. | 0.030 max. | / | / | / |

| STH21 | 0.25 to 0.35 | 0.15 to 0.35 | 0.40 to 0.90 | 0.030 max. | 0.030 max. | 0.25 max | 0.80 to 1.2 | 0.15 to 0.3 |

| STH22 | 0.33 to 0.80 | 0.15 to 0.35 | 0.40 to 0.90 | 0.030 max. | 0.030 max. | 0.25 max | 0.80 to 1.2 | 0.15 to 0.3 |

| STH31 | 0.35 to 0.40 | 0.10 to 0.50 | 1.20 to 1.50 | 0.030 max. | 0.030 max. | 0.50 to 1.00 | 0.30 to 0.60 | 0.15 to 0.25 |

Our Advantages

1.HengYang or TPCO high-quality special steel and its high purity of steel.

2.its wall thickness uniformity and high precision, light quality, productivity and yield is quite high, also facilitate cylinder manufactory convergent,

3.We could produce cylinder pipe diameter can be done in 40 ~ 944.4mm, the minimum wall thickness of 3.5 mm,

4.As a conventional specification of gas cylinders, the delivery time is faster.

Various types of carbon steel tubes/pipes to meet your needs

| Material | API SPEC 5L | A25, A25A, B, X42, X46, X52, X56, X60, X65, X70, X80, X90, X100 | |

| ASTM A53/ASME SA53 | Grade A, Grade B, | ||

| ASTM A106/ASME SA106 | Grade A, Grade B, Grade C | ||

| ASTM A210/ASME SA210 | Grade A-1, Grade C | ||

| ASTM A500/ASME SA500 | Grade A, Grade B, Grade C, Grade D | ||

| ASTM A501/ASME SA501 | Grade A, Grade B | ||

| ASTM A556/ASME SA556 | Grade A2, B2, C2 | ||

| BS 3059 | 320, 360, 440, 620-460, 629-590, 762 | ||

| EN 10216-1&2 | P195, P235, P265 | ||

| EN10297-2 | E235, E275, E315, E355a, E470, C22E, C35E, C45E | ||

| EN10210-1 | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H | ||

| DIN 1629 | st37.0, st44.0, st52.0 | ||

| DIN 1630 | st37.4, st44.4, st52.4 | ||

| DIN 2391 | st35, st45, st52 | ||

| DIN 17175 | st35.8, st45.8 | ||

| JIS G3429 | STH11, STH 12 | ||

| JIS G3444 | STK290, STK400, STK500, STK490, STK540 | ||

| JIS G3454 | STPG370, STPG410 | ||

| JIS G3455 | STS370, STS410, STS480 | ||

| JIS G3456 | STPT370, STPT410, STPT480 | ||

| JIS G3460 | STPL380 | ||

| JIS G3461 | STB340, STB410, STB510 | ||

| JIS G3464 | STBL380 | ||

| JIS G3475 | STKN400W, STKN400B, STKN490B | ||

| Size | O.D:6-2500mm W.T:0.9-120mm Length: 5.8m, 6m, 11.8m, 12m, or as required. | ||

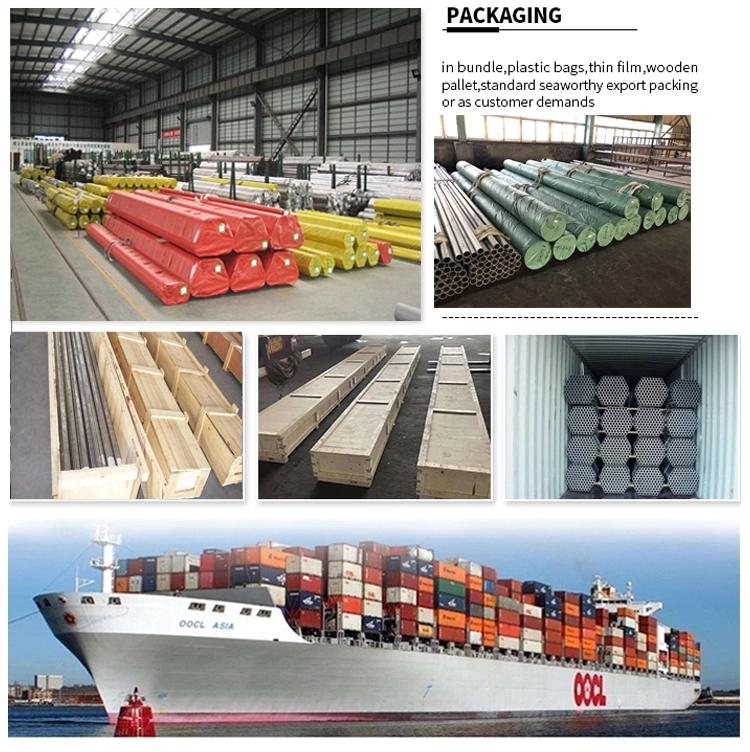

| Technique | 1) Hot Rolled | Package | 1) Export standard package |

| 2) Cold Drawn | 2) bundled wooden box | ||

| 3) Cold Rolled | 3) suit for all kinds of transport, or be require | ||

Shipping&Package