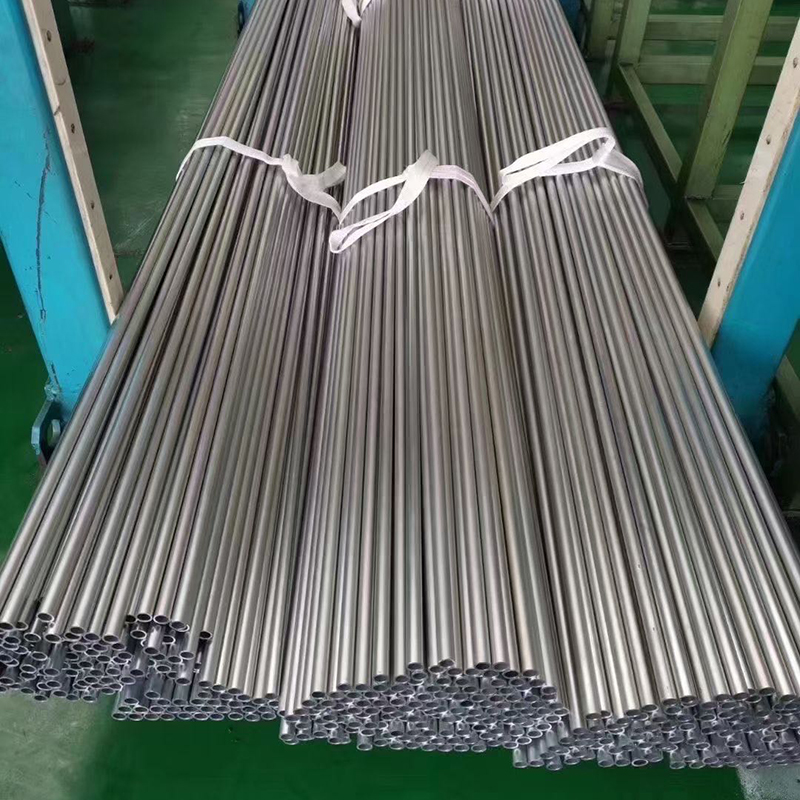

JIS3445 Stkm11A 12A 13A Auto Tube

We are proud of the high customer satisfaction and wide acceptance due to our persistent pursuit of high quality both on product and service for JIS3445 Stkm11A 12A 13A Auto Tube, In addition, we would properly guideline the customers about the application techniques to adopt our solutions and the way to select appropriate materials.

We are proud of the high customer satisfaction and wide acceptance due to our persistent pursuit of high quality both on product and service for stkm11a auto tube, Stkm11a Steel Tube, We set “be a creditable practitioner to achieve the continuous development and innovation” as our motto. We would like to share our experience with friends at home and abroad, as a way to create a bigger cake with our joint efforts. We’ve several experienced R & D persons and we welcome OEM orders.

Features

Material Grade:

STKM 11A 12A 12B 12C 13A 13B 13C 14A 14B 14C 15A 15C etc.

Surface Treatment:

1.Bared

2.Black Painted (varnish coating)

3.Galvanized

4.Oiled

5.According to customers.

JIS G3445 Precision steel tubes are mainly used in automobile and precision machinery parts for cars and cylinder. pressure use, and also for transporting steam, water, gas pipe lines.

Chemical composition

| Grade | Designation | Unit (%) | ||||||

| C | Si | Mn | P | S | Nb or V | |||

| Grade 11 | A | STKM 11A | 0.12 max. | 0.35 max. | 0.60 max. | 0.040 max. | 0.040 max. | - |

| Grade 12 | A | STKM 12A | 0.20 max. | 0.35 max. | 0.6 max. | 0.04 max. | 0.04 max. | |

| B | STKM 12B | |||||||

| C | STKM 12C | |||||||

| Grade 13 | A | STKM 13A | 0.25 max. | 0.35 max. | 0.30~0.90 | 0.040 max. | 0.040 max. | - |

| B | STKM 13B | |||||||

| C | STKM 13C | |||||||

| Grade 14 | A | STKM 14A | 0.30 max. | 0.35 max. | 0.30~1.00 | 0.040 max. | 0.040 max. | - |

| B | STKM 14B | |||||||

| C | STKM 14C | |||||||

| Grade 15 | A | STKM 15A | 0.25~0.35 | 0.35 max. | 0.30~1.00 | 0.040 max. | 0.040 max. | - |

| C | STKM 15C | |||||||

| Grade 16 | A | STKM 16A | 0.35~0.45 | 0.40 max. | 0.40~1.00 | 0.040 max. | 0.040 max. | - |

| C | STKM 16C | |||||||

| Grade 17 | A | STKM 17A | 0.45~0.55 | 0.40 max. | 0.40~1.00 | 0.040 max. | 0.040 max. | - |

| C | STKM 17C | |||||||

| Grade 18 | A | STKM 18A | 0.18 max. | 0.55 max. | 1.50 max. | 0.040 max. | 0.040 max. | - |

| B | STKM 18B | |||||||

| C | STKM 18C | |||||||

| Grade 19 | A | STKM 19A | 0.25 max. | 0.55 max. | 1.50 max. | 0.040 max. | 0.040 max. | - |

| C | STKM 19C | |||||||

| Grade 20 | A | STKM 20A | 0.25 max. | 0.55 max. | 1.60 max. | 0.040 max. | 0.040 max. | 0.15 max |

Mechanical properties

|

Steel Grade |

Yield Strength (Mpa) | Tensile Strength (Mpa) | Elongation(%) | |

|

Name |

No. |

ReH (min) | Rm(min) |

A(min) |

|

STKM 11A |

|

_ |

290 |

35 |

|

STKM 12A |

|

175 |

340 |

35 |

|

STKM 12B |

|

275 |

390 |

25 |

|

STKM 12C |

|

355 |

4700 |

20 |

|

STKM13A |

|

215 |

370 |

30 |

|

STKM 11B |

|

305 |

440 |

20 |

|

STKM11C |

|

380 |

510 |

15 |

Tolerance

| SIZE | Allowable tolerance | Special Tolerance | ||

| OD | WT | OD | WT | |

| 4mm-20mm | ±0.25mm | <3mm±0.3mm;

≥3mm ±10%

|

±0.05mm | ±0.05mm |

| 20mm-30mm | ±0.25mm | ±0.08mm | ±0.08mm | |

| 31mm-40mm | ±0.25mm | ±0.10mm | ±0.08mm | |

| 41mm-49mm | ±0.25mm | ±0.15mm | ±0.15mm | |

| 50mm-80mm | ±0.5% | ±0.20mm | ±0.20mm | |

| 81mm-120mm | ±0.5% | ±0.30mm | ±0.30mm | |

Delivery condition

| Designation | Symbol | Description |

| Cold finished (hard) | BK(+C) | Tubes do not undergo heat treatment following the final cold forming and, thus, have a rather high resistance to deformation |

| Cold finished (Soft) | BKW | The final heat treatment is followed by cold drawing involving limited deformation. Appropriate further processing allows a certain degree of cold forming (e.g. bending, expanding) |

| (+LC) | ||

| Cold finished and stress-relieved | BKS(+SR) | Heat treatment is applied following the last cold forming process. Subject to appropriate processing conditions, the increase in the residual stresses involved enables both forming and machining to a certain degree. |

| Annealed | GBK(+A) | The last Cold forming process is followed by annealing in a controlled atmosphere. |

| Normalized | NBK(+N) | The last cold forming process is followed by annealing above the upper transformation point in a controlled atmosphere. |

| High Precision Steel Tubes in Stock | ||||||||||

| OD | Thickness(mm) | |||||||||

| mm | ||||||||||

| 4 | 4*1 | |||||||||

| 6 | 6*1 | 6*1.5 | 6*2 | |||||||

| 8 | 8*1 | 8*1.5 | 8*2 | |||||||

| 10 | 10*1 | 10*1.5 | 10*2 | 10*2.5 | ||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | 12*3 | |||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | |||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | 15*3.5 | ||||

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | 16*3.5 | 16*4 | 16*4.5 | ||

| 18 | 18*1 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | 18*4.5 | ||

| 20 | 20*1 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | 20*4.5 | 20*5 | |

| 22 | 22*1 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | 22*4.5 | 22*5 | |

| 25 | 25*1 | 25*1.5 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | 25*4.5 | 25*5 | |

| 28 | 28*1 | 28*1.5 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | 28*4.5 | 28*5 | |

| 30 | 30*1 | 30*1.5 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | 30*6 |

| 32 | 32*1.5 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | 32*6 | |

| 34 | 34*1.5 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |

| 35 | 35*1.5 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | ||

| 40 | 40*2 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||

| 42 | 42*2 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||

| 45 | 45*2 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||

| 46 | 46*2 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||

| 48 | 48*2 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||

| 50 | 50*2 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||

| 54 | 54*2.5 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||

| 60 | 60*2.5 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | |||

| 65 | 65*3 | 65*3.5 | 65*4 | 65*4.5 | 65*5 | 65*6 | ||||

| 75 | 75*3.5 | 75*4 | 75*4.5 | 75*5 | 75*6 | |||||

| 76 | 76*4 | 76*4.5 | 76*5 | 76*6 | ||||||

| 89 | 89*6 | |||||||||

| Note: We could produce other sizes as your requirements. Surface Treatment: Bright, Galvanized, Phosphate etc. | ||||||||||

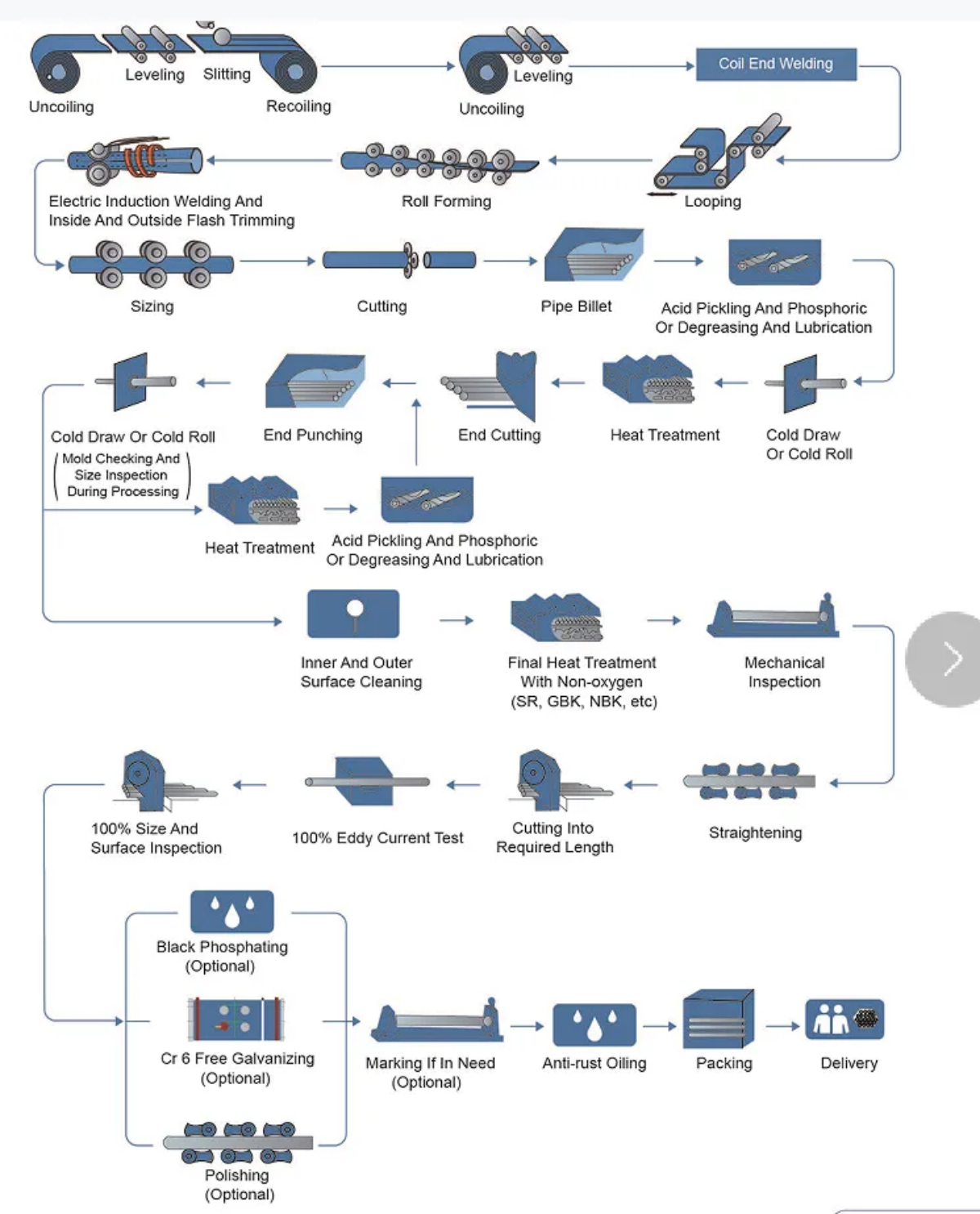

Manufacture Process

Advantages

Strengthen the inspection of products in each production stage, equipped with complete testing equipment: non-destructive eddy current testing, high pressure resistance testing machine, universal mechanical tensile testing machine, bending flattening flares testing machine, cleanliness analyzer, metal element analyzer, etc. Meet the mechanical properties of products, process performance test, provide a powerful guarantee for qualified products .

Quality assurance

1. Strict according to JIS G3445 Standard or other standards.

2. Sample: Sample is free for test.

3. Tests: Salt spray test/Tensile test / Eddy current / Chemical composition test according to customers’ request

4.Certificate: IATF16949, ISO9001, SGS etc.

5.EN 10204 3.1 Certification

STKM11A is a material grade in Japan, mainly referring to carbon steel pipes for mechanical structures.

Alloy composition content:

C: 0.12% Si: 0.35% Mn: 0.60% P: 0.04% S: 0.04% 4. Mechanical properties:

The hardness and hardness of STKM11a steel pipe are 950HV, and the tensile strength is determined by its strength σ B (MPa): ≥ 295 elongation δ/%: Longitudinal ≥ 35, transverse ≥ 30 structural steel should pay attention to hardness. STKM11 is a common carbon steel, and STKM11A is a steel grade for carbon steel pipes used in mechanical structures. It is a Japanese grade corresponding to China’s national standard steel pipe 10 # steel.

We are proud of the high customer satisfaction and wide acceptance due to our persistent pursuit of high quality both on product and service for Quoted price for JIS3445 Stkm11A 12A 13A Auto Tube, In addition, we would properly guideline the customers about the application techniques to adopt our solutions and the way to select appropriate materials.

Quoted price for China Seamless Steel Pipe and Pipe Fitting, We set “be a creditable practitioner to achieve the continuous development and innovation” as our motto. We would like to share our experience with friends at home and abroad, as a way to create a bigger cake with our joint efforts. We’ve several experienced R & D persons and we welcome OEM orders.