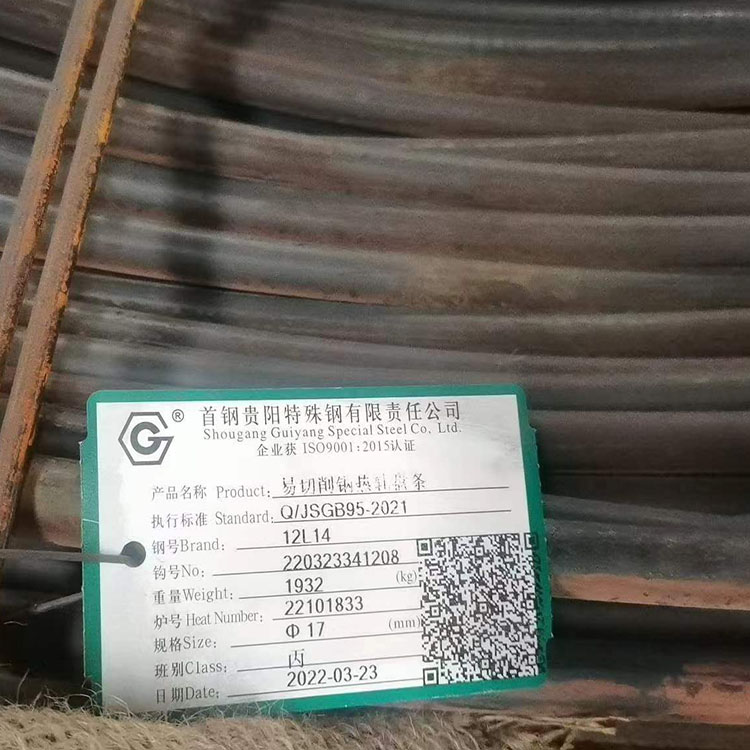

Manufacturer for SAE 1215 / AISI 1215 Cold Drawn Free Cutting Steel Round Bars

Our enterprise insists all along the quality policy of “product high-quality is base of organization survival; customer gratification will be the staring point and ending of an company; persistent improvement is eternal pursuit of staff” and also the consistent purpose of “reputation very first, purchaser first” for Manufacturer for SAE 1215 / AISI 1215 Cold Drawn Free Cutting Steel Round Bars, Because we stay in this line about 10 years. We got best suppliers support on quality and price. And we had weed out suppliers with poor quality. Now many OEM factories cooperated with us too.

Our enterprise insists all along the quality policy of “product high-quality is base of organization survival; customer gratification will be the staring point and ending of an company; persistent improvement is eternal pursuit of staff” and also the consistent purpose of “reputation very first, purchaser first” for 1215 steel bar, aisi1215 cold drawn free cutting round bar, we’ve got complete material production line, assembling line , quality control system, and the most importantly, we have many patents technology and experienced technical&production team, specialist sales service team. With all these advantages, we are gonna create”the reputable international brand of nylon monofilaments”, and spreading our goods to every corner of the world. We have been keep moving and try our best to serve our customers.

Product Detail

ASTM AISI 1212 1215 1140 1144 Free Cutting Steel bar are high sulfur medium-low carbon free-cutting steel, which has better cutting performance compared with 10# 25# 35# 45# steel, ASTM 1212 1215 1140 1144 can increase tool life by four times, increase productivity by 30%, and has higher strength and hardness.

Standard: ASTM A29/A29M-04

ASTM AISI 1212 1215 1140 1144 Free cutting steel are metal material that has good wear resistance and impact resistance. Free cutting steel is commonly used in the manufacturing of components, tools, or other equipment, such as machine tool blades, valve body clamps, etc. ASTM1212 1215 1140 1144 free cutting steel have excellent wear resistance, corrosion resistance, and oxidation resistance, so it can be widely used in various mechanical processing fields. ASTM1212 1215 1140 1144 free cutting steel exhibits excellent wear resistance at high temperatures, while at low temperatures it exhibits good compressive and extramural strength. In addition, the steel also has very high tensile strength and can withstand heavy loads. ASTM1212 1215 1140 1144 free cutting steel have excellent heat resistance and will not burn even when heated in flames.

Parameters

|

Size |

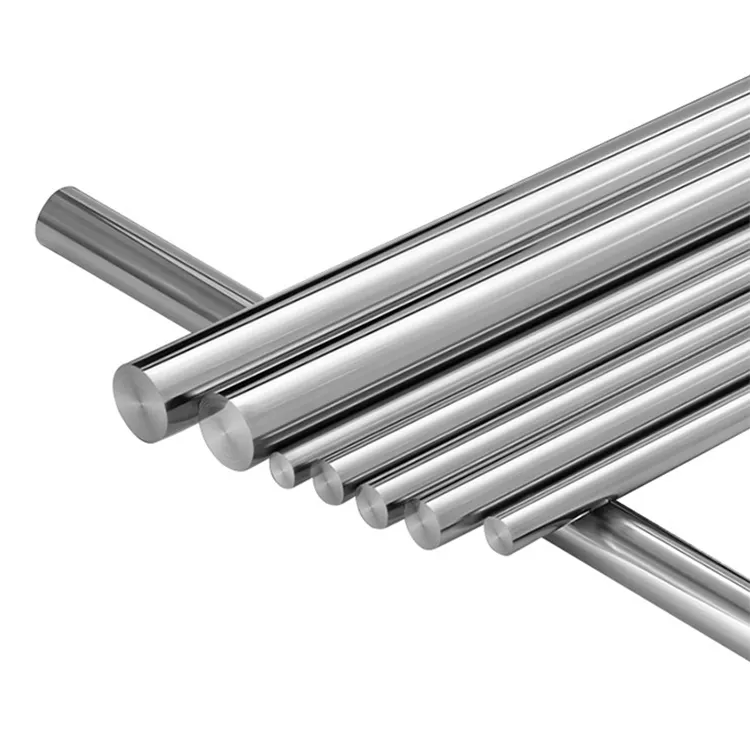

Round Bar | Dia 6-1200mm |

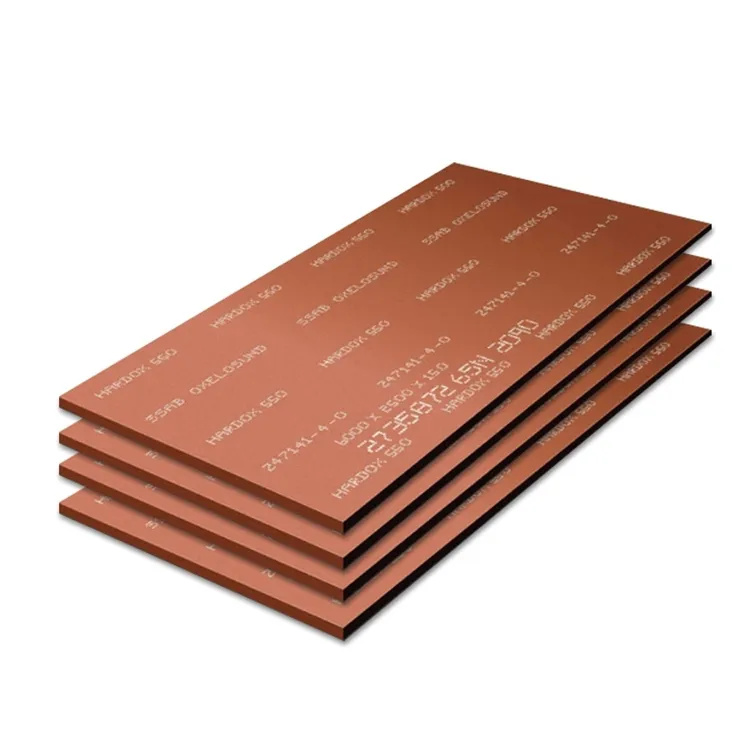

| Plate/Flat/Block | Thickness: 6mm-500mm | |

| Width: 20mm-1000mm | ||

| Heat treatment | Normalized ; Annealed ; Quenched ; Tempered | |

| Type | Cold drawn/hot rolled | |

| Surface condition | Black; Peeled; Polished; Machined; Grinded; Turned; Milled | |

| Delivery condition | Forged; Hot rolled; Cold drawn | |

| Test | Tensile strength, Yield strength, elongation, area of reduction, impact value, hardness, grain size, ultrasonic test, US inspection, magnetic particle testing, etc. | |

| Application | ASTM 1212 1215 1140 1144 are suitable for machining parts requiring high rigidity, such as lead screw, polished rod, rack and spline shaft, etc. | |

| Chemical Composition (%) | ||||

|

Grade |

C |

Mn |

P |

S |

|

1212 |

≤0.13 |

0.70-1.00 |

0.07-0.12 |

0.16-0.23 |

|

1215 |

≤0.09 |

0.75-1.05 |

0.04-0.09 |

0.24-0.33 |

|

1140 |

0.37-0.44 |

0.7-1.0 |

≤0.04 |

0.08-0.13 |

|

1144 |

0.40-0.48 |

1.35-1.65 |

≤0.04 |

0.24-0.33 |

| Equal different standards | ||||

|

AISI/ASTM |

GB |

EN10087 |

JIS |

DIN |

|

1212 |

Y12 |

- |

SUM21 |

- |

|

1215 |

Y15 |

11SMn30 |

- |

- |

|

1140 |

Y35 |

- |

SUM41 |

- |

|

1144 |

Y40Mn |

38SMn28 |

SUM43 |

44Mn28 |

Package&Shipping

Quality Assurance

1.Strict according to Requirements

2.Sample: Sample is available.

3. Tests: Salt spray test/Tensile test / Eddy current / Chemical composition test according to customers’ request

4.Certificate: IATF16949, ISO9001, SGS etc.

5. EN 10204 3.1 Certification

SAE /AISI 1215 free cutting steel bar is a type of easy cutting steel with good machining performance, widely used in mechanical parts, shafts, instruments and other fields.

The main components of 1215 free cutting steel are carbon, manganese, and sulfur, with a higher sulfur content, which can improve the cutting performance of the steel. The hardness of 1215 steel is around 135-180HBW, with good machinability and a smooth machined surface. The specific gravity of 1215 steel is 7.85g/cm ³, Similar to ordinary steel.

1215 steel is mainly used for manufacturing parts and components, such as bolts, nuts, pins, etc. Due to its ease of processing and high production efficiency, 1215 steel is widely used in mass production. In addition, 1215 steel can also be used to manufacture high-strength mechanical and structural components.

The processing technology of 1215 steel mainly includes two methods: heat treatment and cold processing. The heat treatment method includes quenching and tempering, which can improve the hardness and strength of the steel. Cold working methods include stretching, stamping, shearing, etc., which can make steel have higher strength and toughness. 1215 steel also has good welding performance and can be welded using methods such as argon arc welding and resistance welding. For surface treatment, 1215 steel can be treated by methods such as pickling and electroplating to improve surface smoothness and corrosion resistance.

The main advantages of 1215 steel are easy processing, low cost, high strength, and good wear resistance, making it suitable for mass production. However, 1215 steel has a high sulfur content and is prone to hydrogen embrittlement. At the same time, it is prone to annealing and softening at high temperatures, making it unsuitable for use in harsh environments such as high temperatures and pressures.