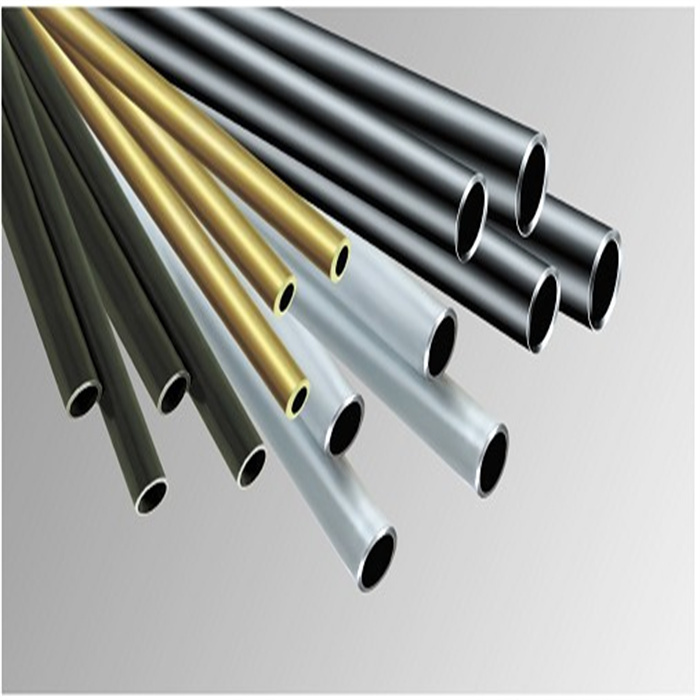

OEM/ODM Manufacturer St37 DIN1626 German Standard Precision Carbon Steel Seamless Pipe Tubing

We often persist with the theory “Quality To start with, Prestige Supreme”. We are fully committed to delivering our clientele with competitively priced good quality items, prompt delivery and experienced support for OEM/ODM Manufacturer St37 DIN1626 German Standard Precision Carbon Steel Seamless Pipe Tubing, We are hunting ahead to cooperating with all buyers from in your own home and abroad. Moreover, customer pleasure is our everlasting pursuit.

We often persist with the theory “Quality To start with, Prestige Supreme”. We are fully committed to delivering our clientele with competitively priced good quality items, prompt delivery and experienced support for China Precision Seamless Steel Pipe and Seamless Pipe, We are looking forward to establishing a mutually beneficial relationship with you based on our high-quality products, reasonable prices and best service. We hope that our products will bring you a pleasant experience and carry a feeling of beauty.

Product Detail

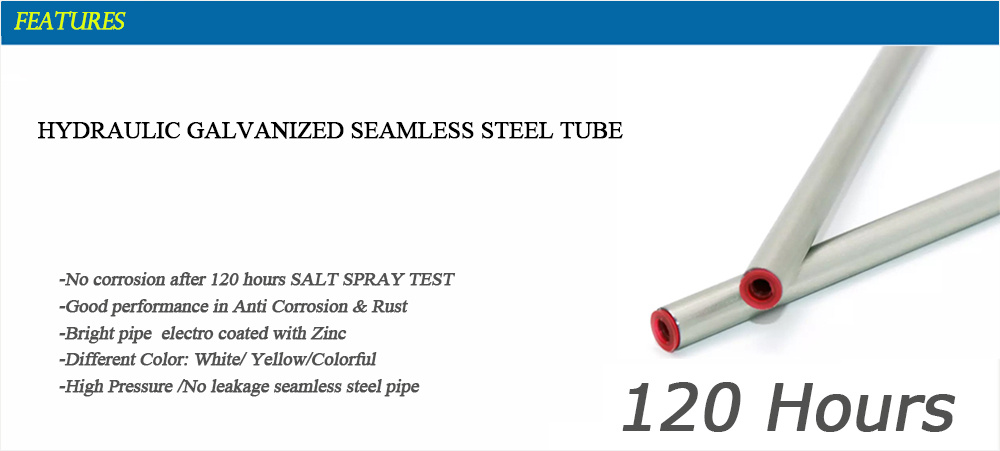

DIN2391 High Pressure hydraulic Galvanized Steel Tubing is produced basing on DIN 2391-C. It is widely used in hydraulic systems, machine tools, automobiles, ships, construction machinery and vehicles. The Hydraulic galvanized seamless steel tube with high precision has lots of advantages: No corrosion after 120 hours SALT SPRAY TEST; Good performance in Anti Corrosion & Rust; Bright pipe electric coated with Zinc; Different Color: White/ Yellow/Colorful; High Pressure /No leakage seamless steel pipe.

Specification

|

Standard |

DIN2391 DIN1630 EN10305 DIN2445 JIS G3445 SAE J524 |

|

Grade |

ST35/E235 ST37.4 ST45/E255 ST52/E355 |

|

Delivery Condition |

NBK(+N) BK(+C) GBK(+A) BKW(+LC) BKS(+SR) |

|

Size |

OD:4 to 219mm Thickness 0.5-35mm, Length: 3m,5.8,6 or according to requirements |

|

Finish |

Galvanized surface (Sliver/Yellow/Colorful) Zinc coating of 8-12um |

|

Application |

Hydraulic System; Car/bus; construction vehicle |

|

Delivery time |

A.3 days if this good is stock goods. B. About 30 days according to the quantity |

|

HYDRAULIC PRECSION STEEL TUBE IN STOCK |

||||||||||

|

OD |

Thickness(mm) |

|||||||||

|

mm |

|

|||||||||

|

4 |

4*1 |

|

|

|

|

|

|

|

|

|

|

6 |

6*1 |

6*1.5 |

6*2 |

|

|

|

|

|

|

|

|

8 |

8*1 |

8*1.5 |

8*2 |

|

|

|

|

|

|

|

|

10 |

10*1 |

10*1.5 |

10*2 |

10*2.5 |

|

|

|

|

|

|

|

12 |

12*1 |

12*1.5 |

12*2 |

12*2.5 |

12*3 |

|

|

|

|

|

|

14 |

14*1 |

14*1.5 |

14*2 |

14*2.5 |

14*3 |

|

|

|

|

|

|

15 |

15*1 |

15*1.5 |

15*2 |

15*2.5 |

15*3 |

15*3.5 |

|

|

|

|

|

16 |

16*1 |

16*1.5 |

16*2 |

16*2.5 |

16*3 |

16*3.5 |

16*4 |

16*4.5 |

|

|

|

18 |

18*1 |

18*1.5 |

18*2 |

18*2.5 |

18*3 |

18*3.5 |

18*4 |

18*4.5 |

|

|

|

20 |

20*1 |

20*1.5 |

20*2 |

20*2.5 |

20*3 |

20*3.5 |

20*4 |

20*4.5 |

20*5 |

|

|

22 |

22*1 |

22*1.5 |

22*2 |

22*2.5 |

22*3 |

22*3.5 |

22*4 |

22*4.5 |

22*5 |

|

|

25 |

25*1 |

25*1.5 |

25*2 |

25*2.5 |

25*3 |

25*3.5 |

25*4 |

25*4.5 |

25*5 |

|

|

28 |

28*1 |

28*1.5 |

28*2 |

28*2.5 |

28*3 |

28*3.5 |

28*4 |

28*4.5 |

28*5 |

|

|

30 |

30*1 |

30*1.5 |

30*2 |

30*2.5 |

30*3 |

30*3.5 |

30*4 |

30*4.5 |

30*5 |

30*6 |

|

32 |

|

32*1.5 |

32*2 |

32*2.5 |

32*3 |

32*3.5 |

32*4 |

32*4.5 |

32*5 |

32*6 |

|

34 |

|

34*1.5 |

34*2 |

34*2.5 |

34*3 |

34*3.5 |

34*4 |

34*4.5 |

34*5 |

34*6 |

|

35 |

|

35*1.5 |

35*2 |

35*2.5 |

35*3 |

35*3.5 |

35*4 |

35*4.5 |

35*5 |

35*6 |

|

38 |

|

|

38*2 |

38*2.5 |

38*3 |

38*3.5 |

38*4 |

38*4.5 |

38*5 |

38*6 |

|

40 |

|

|

40*2 |

40*2.5 |

40*3 |

40*3.5 |

40*4 |

40*4.5 |

40*5 |

40*6 |

|

42 |

|

|

42*2 |

42*2.5 |

42*3 |

42*3.5 |

42*4 |

42*4.5 |

42*5 |

42*6 |

|

45 |

|

|

45*2 |

45*2.5 |

45*3 |

45*3.5 |

45*4 |

45*4.5 |

45*5 |

45*6 |

|

46 |

|

|

46*2 |

46*2.5 |

46*3 |

46*3.5 |

46*4 |

46*4.5 |

46*5 |

46*6 |

|

48 |

|

|

48*2 |

48*2.5 |

48*3 |

48*3.5 |

48*4 |

48*4.5 |

48*5 |

48*6 |

|

50 |

|

|

50*2 |

50*2.5 |

50*3 |

50*3.5 |

50*4 |

50*4.5 |

50*5 |

50*6 |

|

54 |

|

|

|

54*2.5 |

54*3 |

54*3.5 |

54*4 |

54*4.5 |

54*5 |

54*6 |

|

60 |

|

|

|

60*2.5 |

60*3 |

60*3.5 |

60*4 |

60*4.5 |

60*5 |

60*6 |

|

65 |

|

|

|

|

65*3 |

65*3.5 |

65*4 |

65*4.5 |

65*5 |

65*6 |

|

75 |

|

|

|

|

|

75*3.5 |

75*4 |

75*4.5 |

75*5 |

75*6 |

|

76 |

|

|

|

|

|

|

76*4 |

76*4.5 |

76*5 |

76*6 |

|

89 |

|

|

|

|

|

|

|

|

|

89*6 |

| Note: We could produce other sizes as your requirements. Surface Treatment: Bright, Galvanized, Phosphating etc. | ||||||||||

Chemical Composition

|

Steel Grade |

C |

Si |

Mn |

P |

S |

Al |

|

|

Name |

No. |

max |

max |

max |

max |

max |

max |

|

E215 |

1.0212 |

0.1 |

0.05 |

0.7 |

0.025 |

0.015 |

0.025 |

|

E235 |

1.0308 |

0.17 |

0.35 |

1.2 |

0.025 |

0.015 |

— |

|

E355 |

1.058 |

0.22 |

0.55 |

1.6 |

0.025 |

0.015 |

— |

|

ST35 |

1.0308 |

0.17 |

0.35 |

0.4(min) |

0.025 |

0.025 |

— |

|

ST45 |

1.0408 |

0.21 |

0.35 |

0.4(min) |

0.025 |

0.025 |

— |

|

ST52 |

1.058 |

0.22 |

0.55 |

1.6 |

0.025 |

0.025 |

— |

Mechanical properties

|

Steel Grade |

Yield Strength (Mpa) | Tensile Strength (Mpa) | Elongation(%) | |

|

Name |

No. |

ReH (min) | Rm(min) |

A(min) |

|

E215 |

1.0212 |

215 |

290 to 430 |

30 |

|

E235 |

1.0308 |

235 |

340 to 480 |

25 |

|

E355 |

1.058 |

355 |

490 to 630 |

22 |

|

ST35 |

1.0308 |

235 |

340 to 480 |

25 |

|

ST45 |

1.0408 |

255 |

440 to 570 |

21 |

|

ST52 |

1.058 |

355 |

490 to 630 |

22 |

Tolerance

|

OD |

Allowable tolerance |

Special Tolerance |

||

|

|

GB/T3639 |

DIN2391 |

OD |

WT |

|

4mm-20mm |

±0.10mm |

±0.08mm |

±0.05mm |

±0.05mm |

|

20mm-30mm |

±0.10mm |

±0.08mm |

±0.08mm |

±0.08mm |

|

31mm-40mm |

±0.15mm |

±0.15mm |

±0.10mm |

±0.08mm |

|

41mm-60mm |

±0.20mm |

±0.20mm |

±0.15mm |

±0.15mm |

|

61mm-80mm |

±0.30mm |

±0.30mm |

±0.20mm |

±0.20mm |

|

81mm-120mm |

±0.45mm |

±0.45mm |

±0.30mm |

±0.30mm |

Delivery Condition

|

Designation |

Symbol |

Description |

| Cold finished (hard) | BK(+C) | Tubes do not undergo heat treatment following the final cold forming and, thus, have a rather high resistance to deformation |

| Cold finished (Soft) | BKW | The final heat treatment is followed by cold drawing involving limited deformation. Appropriate further processing allows a certain degree of cold forming (e.g. bending, expanding) |

| (+LC) | ||

| Cold finished and stress-relieved | BKS(+SR) | Heat treatment is applied following the last cold forming process. Subject to appropriate processing conditions, the increase in the residual stresses involved enables both forming and machining to a certain degree. |

| Annealed | GBK(+A) | The last Cold forming process is followed by annealing in a controlled atmosphere. |

| Normalized | NBK(+N) | The last cold forming process is followed by annealing above the upper transformation point in a controlled atmosphere. |

Quality Assurance

1. Strict according to DIN2391/EN10305 or other standard.

2. Sample: Sample is free for test.

3. Tests: Salt spray test/Tensile test / Eddy current / Chemical composition test according to customers’ request

4.Certificate: IATF16949, ISO9001, SGS etc.

5.EN 10204 3.1 Certification

Application

Product package

We often persist with the theory “Quality To start with, Prestige Supreme”. We are fully committed to delivering our clientele with competitively priced good quality items, prompt delivery and experienced support for OEM/ODM Manufacturer St37 DIN1626 German Standard Precision Carbon Steel Seamless Pipe Tubing, We are hunting ahead to cooperating with all buyers from in your own home and abroad. Moreover, customer pleasure is our everlasting pursuit.

OEM/ODM Manufacturer China Precision Seamless Steel Pipe and Seamless Pipe, We are looking forward to establishing a mutually beneficial relationship with you based on our high-quality products, reasonable prices and best service. We hope that our products will bring you a pleasant experience and carry a feeling of beauty.