Turned Ground and Polished Steel Bar TGP Round Bar

Features

Turned Ground and Polished Steel bar is a silver bright steel produced by processing hot-rolled steel through processes such as annealing, cold drawing, and polishing. It has the characteristics of high dimensional accuracy and good surface quality. Especially for polished materials, which effectively remove surface decarburization layers, surface cracks, and various external defects. They are widely used in industries such as mechanical equipment manufacturing, electronics, petroleum, chemical, automotive, railway, shipbuilding, aerospace, nuclear power, etc.

Our company has a production capacity of 20000 tons/year, advanced production technology, excellent product quality, and products with high precision, high straightness, and high roundness.

Product varieties: high-quality carbon structural steel, alloy structural steel, bearing steel, spring steel, easy cutting steel, etc.

Specification

| Size | Φ10-330mm |

| Length | 0.5-11m |

| Material | SAE1045 S45C CK45 Gcr15 4140 40Cr 27SiMn etc |

| Tolerance | h9~h11 etc( DIN7155 Sthandard or as requirement) |

| Chrome Thickness | 15-30μmm |

| Hardness | According to Delivery Condition |

| Roughness | Ra 0.3μm(max) |

| Straightness | 0.5/1000 mm |

| Yield Strength | >320Mpa (As steel grade ) |

| Tensile Strength | >580Mpa (As steel grade ) |

| Elongation | >15% (As steel grade ) |

| Condition | 1.Hard chrome plated |

| 2.No heat treatment | |

| 3.Quenched& Tempered | |

| 4.Induction hardened with Q&T | |

| Application | Hydraulic shafting, pneumatic piston rods, pump shafting, precision piston rods, guide rods etc |

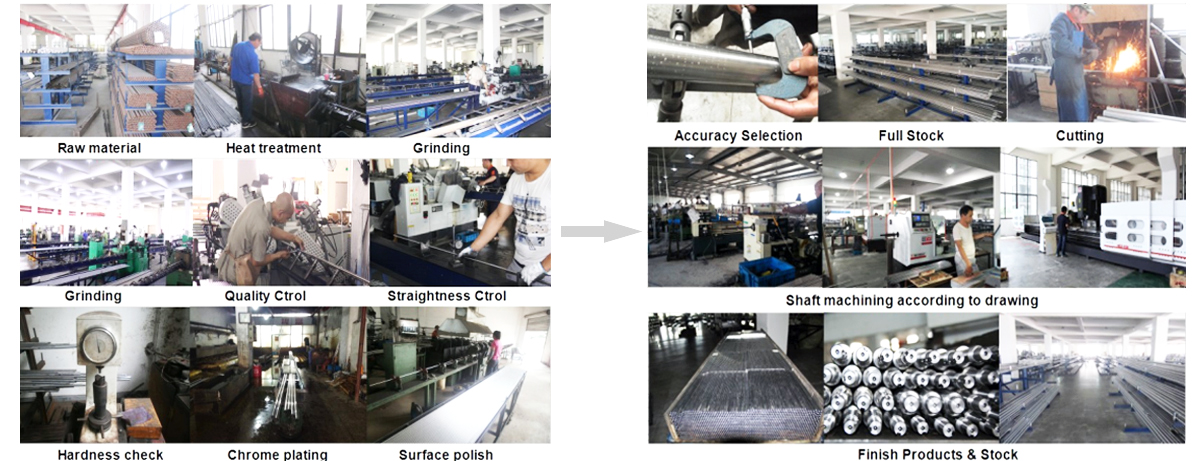

Manufacture Process

Turned Ground and Polished Steel bar produce process:

Choose raw material(steel bar)→heat treatment(QT)→grinding→quality control(tolerance test)→straight→hardness test→surface polish→accuracy section→dipped anti rust oil →full stock→cutting→finish products→delivery.

Quality assurance

1. Strict according to standard and requirements

2. Sample: Sample is free for test.

3. Tests: Tensile test / Eddy current / Chemical composition test according to customers' request

4.Certificate: IATF16949, ISO9001, SGS etc.

5. EN 10204 3.1 Certification

FAQ

Q1: Do you accept small order?

A: If your order bearings are our standard size, we accept even 1pcs.

Q2: Can I get free sample?

A: Yes. Limited,free sample available, freight cost must be paid by your side.

Q3: Are you factory or trade company?

A: We are manufacturer, New Gaopwer Metal factory.

Q4: Can we mark our brand on your bearings and packing?

A: Yes, we support OEM your brand, the details let’s negotiation.

Q5: How long is the delivery?

A: Small orders usually takes 3-7 days,big order usually 20-35 days, depending on orders quantity and whether are standard size.

Payment

TT, Western Union, Paypal, L/C.

Transport:

1: DHL, FEDEX,TNT, UPS, EMS

2: By sea, By air.